Discover our innovations in materials engineering

Our pioneering team develops cutting-edge ceramics, metals and their composites tailored for diverse applications.

We're passionate about expanding the boundaries of the most novel materials in Türkiye.

Our Expert Team:

Our Expertise:

Our R&D team of three highly qualified experts, each with a PhD from prestigious German technical universities, has an extensive track record of over two decades in European industrial projects, marked by over 40 patents and several academic publications, led by Kaan Özer, our CEO with an MBA in International Management Consulting from Germany.

Comprehensive R&D Services:

We offer a comprehensive suite of customized R&D services, guiding clients through each stage of product development - from raw powder material designing up to the final implementation of tailored material and process solution in a cost effective mass production.

On-going R&D Activities:

-

Metal-Based Coating Powders

-

Low-cost Titanium Bulk Materials

-

Metal Matrix Composite Armour Plates

-

Ceramic Matrix Composite Armour Plates

-

Advanced Sandwich Armour Concepts

-

Cutting Tool Raw Blanks

-

Technology and Know-how transfer to Türkiye for mass production of the light-weight and high-performance Wankel Aviation Engine

-

Technology and Patent transfer to Türkiye for mass production of

the ultralight-weight Multi-Purpose Helicopter

Material Science

Utilizing our team of specialized material experts, we develop tailored solutions to meet the technical requirements of various industrial applications. By employing our own advanced material design and characterization techniques, we optimize material microstructures for superior performance in need of application.

Process Technologies

We operate our own equipment in southern Germany and have direct access to a range of test machines of institutes and machine manufacturers across Europe, which are related with powder metallurgy and additive manufacturing. Our expertise enables us to deliver scalable and effective material solutions for various industries.

Mass Production Implementation

We are able to translate advanced material concepts into industrial applications, our implementation expert ensures that the developed materials are seamlessly integrated into mass production environments, focusing on consistency in low costs and high qualities.

Our Business Model for Cooperation

Our business model is meticulously crafted to promote collaboration and drive innovation into the Turkish industry. We aim close cooperation with our clients to thoroughly define their specific requirements, technical and financial expectations regarding material performance and their own applications.

Technology Consultation:

We initiate our processes with in-depth consultations, engaging with clients to gain a comprehensive understanding of their unique requirements, objectives, and challenges.

Technology Research:

Our team undertakes extensive research utilizing literature and patent databases to evaluate the current state of material science and identify the latest advancements in research and development in the industry on a global scale.

Material and Process Design:

Drawing on the research findings, we create customized material designs that align with our clients' specifications. This includes outlining the requisite production steps and employing our innovative production technologies to ensure optimal results for the implementation in the industry.

Prototyping and Testing:

We proceed by developing prototypes and conducting rigorous application tests by clients’ site. Throughout this phase, we actively involve our clients to ensure that the developed materials meet or exceed their performance expectations.

Technology & Know-how Transfer:

Upon receiving clients’ approval, we offer two pathways: we can either establish the production line to facilitate serial production for our clients or transfer the complete know-how and technology, empowering them to manage their own production processes independently.

We're passionate about expanding the boundaries of the most novel materials in Türkiye.

Our expert team is at your service, committed to providing tailored product and process solutions that will exceed your expectations in your own applications.

We leverage our qualifications with deep material and process experience to deliver to you exceptional results efficiently, ensure your specific requirements within the highest quality and shortest time slot.

3D TEKNİK METALÜRJİ ARAŞTIRMA GELİŞTİRME SAVUNMA SANAYİ MÜH. VE TİC. LTD. ŞTİ.

BİLKENT CYBERPARK

ANKARA TEKNOLOJİ KÖPRÜSÜ

İLKADİM MAH. YEŞİLVADİ CAD. NO: 41 - İÇ KAPI NO: 36

ÇANKAYA - ANKARA - TÜRKİYE

KAAN ÖZER

+905462437613

Metal-Based Coating Powders

Design and production of steel, titanium and aluminium based powders from advanced alloy systems and optimizing atomization processes as hard-facing wear reduction coatings for enhancing durability and performance in demanding applications especially for the applications in the offshore, mining and defense industry.

Low-cost Titanium Bulk Materials

Developing highly cost-effective titanium grade 5 and 23 ELI bulk materials with optimal microstructure and material features,

available in dimensions up to 450x450x365 mm, for various of industrial applications.

Metal Matrix Composite Armour Plates

Realizing the steel, titanium or aluminum-based composites chemically bonded with ceramic particles, whiskers, blades, balls, or plates, enhancing mechanical properties and performance by combining the toughness and ductility of metal carriers and the hardness and impact resistance of ceramics for armour applications.

Ceramic Matrix Composite Armour Plates

Development of high-performance ceramic plates fabricated from 100% ceramic powders, produced without any kind of binder materials, thereby maximizing strength and reliability with superior ballistic performance and impact resistance for civil and military defense applications.

Advanced Sandwich Armour Material Concept

Realising the most novel sandwich blocks based on titanium, steel, aluminum, or magnesium monoblock carrier bodies, in which ceramic components are locked through cutting-edge chemical bonding processes.

Ultra-Hard Cutting Tool Raw Blanks

Achieving ultra-hard materials, absolutely free of cobalt and tungsten, or any metal binder, enable enhanced machining performance, superior wear resistance, and extended operational lifespan for the cutting tool applications through the utilization of purely, 100% carbides, nitrides, oxides, or their compositions.

Technology and Know-how transfer to Türkiye for producing

the light-weight high-performance Wankel Aviation Engine

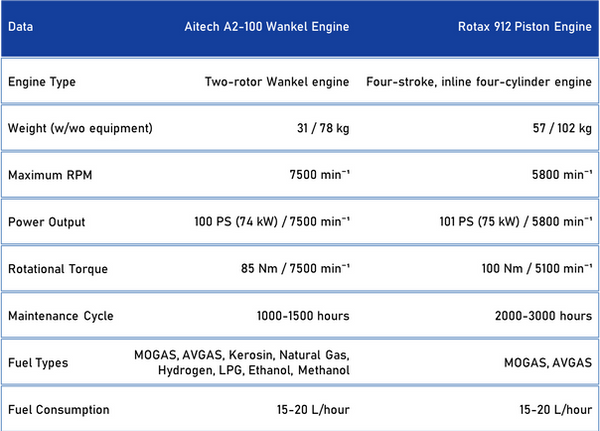

Technology transfer, and implementation of production line of two types of Wankel engines with 50 and 100 ps power.

Know-how Transfer to Türkiye with the whole production and coating machines as well as testing dynos (certification machines) incl. finished spare parts in stockpiles for ca. 50 engines.

These Wankel engines are fully developed, tested and approved engines, with their compact design (less weight & volume), fewer moving parts (cheap and easy production & maintenance), high Power-to-Weight ratio (light-weight), less vibration (smooth operation, less noise),

high RPM capability (high efficiency) and low center of gravity.

Both engines with 50/100 ps at 7500 min⁻¹ have the 19/31 kg dry weights and 68/78 kg fully-equipped weights.

These Wankel engines are perfect alternatives for Rotax912 piston motors.

Technology and Patent transfer to Türkiye for producing

the ultralight-weight Multi-Purpose Helicopter

Modern Modular Design

N55 features a modular design, allowing for easy customization and adaptation to various operational requirements.

Simple Control System

N55's original control system, with its independent channels, enhances piloting ease and user-friendliness.

High Loading Capability

The helicopter's structural configuration facilitates substantial lift capacity, enabling efficient cargo conveyance and high aerial agility.

Compact and Maneuverable

The compact design, agile handling, and superior wind resistance are facilitated by the coaxial rotor configuration.

High-Altitude Performance

Optimized rotor parameters enable the N55 to operate at significant flight altitudes, expanding its operational capabilities.

High strength and reliability

The automated control system and design offer strength, reliability, and exceptional endurance capabilities.

Low Operational Cost

The N55's design and engineering optimization contribute to its cost-effective operation, making it an attractive choice for diverse applications.

Low Noise and Vibration

The aircraft's specially engineered rotor system and design features significantly mitigate noise and vibration, thereby improving the overall flight experience.

Technology Transfer for Mass Production in Türkiye

Road Map in two steps

1) The N55 helicopter (piloted) has been fully developed and approved by European Aero Authorization.

The technology transfer to Türkiye (first step) includes:

-

Delivery of one flying helicopter

-

Resourcing the complete know-how and technical documentation for mass production

-

Transfer of patent rights and necessary press molds for carbon fiber structural components production

-

Engineering support and on-site assistance during production line implementation

-

Technical training for the Turkish team during initial production of the first three helicopters

-

Installation and approval of quality control processes at the production site

2) The development of unmanned (autonomous) N55 helicopter is currently ongoing.

-

Our exxpert team is ready to implement the autonomous flying technology in Türkiye within 6 months

-

Further discussion is needed on the milestones and required profile of the application